Product Center

Product quality is the core of a brand and the life of an enterprise

GuKang Medical Equipment

Strictly regulate management and continuously improve

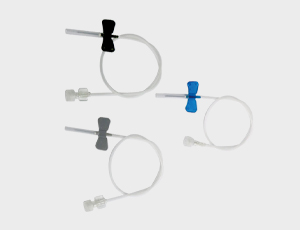

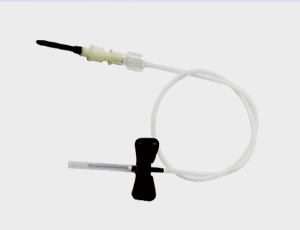

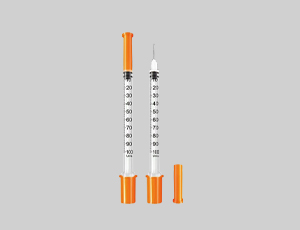

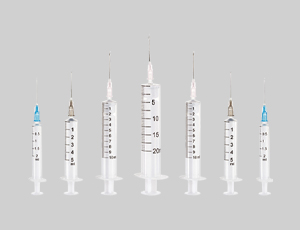

Wuxi Gukang Medical Equipment Co., Ltd. is a transformation and upgrading company of Jiangyin Daqiao Plastic Seal Factory, located in Jiangyin City, an important transportation hub of the Yangtze River Delta, a developed economy in China, and a natural harbor city for river sea intermodal transportation. Guhong Medical is a professional enterprise mainly engaged in the production of medical polymer materials and products, as well as injection puncture equipment. The company has a complete fully automated production line equipment, a 100000 level purification workshop of 2000 square meters, a total investment of 50 million yuan, an annual output of 5 billion rubber stoppers, and 5 million intravenous infusion needles. The company's main products include rubber stoppers, disposable sterile syringes (straight/screw), disposable sterile dissolving syringes (two-piece set), disposable sterile insulin syringes, disposable sterile irrigators, disposable sterile low resistance syringes, disposable sterile infusion needles (double wings), disposable sterile injection needles, disposable lumbar puncture needles, disposable epidural puncture needles, and dozens of other varieties and specifications of products.

-

2000㎡

100000 level purification workshop

-

500000000m

Annual production of rubber plugs by the company (only)

-

5000w

Total investment of the company

Workshop

Medical polymer materials and products, as well as injection puncture equipment

Quality Assurance

Product quality is the core of a brand and the life of an enterprise

-

Strong technical strength

Strong technical strength helps enterprises continuously develop new products and keep up with market trends

-

Further improvement of quality and technology

To conduct technical research and development on problems discovered during inspection and use, in order to continuously optimize and improve the quality of our products

-

After sales quality feedback

Track the quality of factory products and provide timely feedback, while implementing responsibility tracking for each process

-

Finished product inspection

Online inspection of the appearance, smoothness, etc. of each product by frontline operators and workshop dedicated quality inspectors

-

Processing stage

To do a good job, one must first sharpen their tools. The production equipment has a high degree of automation and precise quality control to ensure the quality of the products

-

Rich product variety

Rich product categories can meet the diverse needs of different customers and provide one-stop procurement services for them

News Center

Medical polymer materials and products, as well as injection puncture equipment